Equipment

Quality First All The Time

From high-volume production to small-batch, multi-variety manufacturing,our in-house machines and toolings are perfectly matched to maximize tooling precision and performance.

By handling everything from design to manufacturing and implementation in-house, we deliver optimized solutions for each production process.

We strongly support improved productivity and maintainability at our customers’ production sites through reliable technical expertise.

Press Mold Equipment

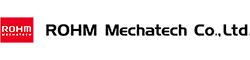

Fusion MEP30

This compact, space-saving device is ideal for prototyping and testing. It supports low-pressure transfer control, allowing for flexible handling of delicate process. With intuitive operation and a wide range of customizable options, it can be tailored to various applications. When combined with our “7Days Experimental Service”, it enables faster and more efficient prototyping and valiation, contributing to a development that balances speed and flexibility.

Specification

| Fusion MEP30 | Resin molding |

|---|---|

| Dimensions | H 1,803mm x W 1,230mm x D 800mm(protrusive part is not included) |

| Weight | 1.2 tons(H/B and toolig not included) |

| Clamping Force | 30 tons (low-pressure control supported) |

| Injection capacity | 0.15 to 1.5 tons (depending on tooling specifications) |

| Compatible Frame Size | Approx. H 100mm x W 170mm (depending on tooling specifications) |

| Number of Pots | 1 to 5 pieces (multi-pot available as an option) |

| Tablet Size | Φ10mm to φ20mm (depending on tooling specifications) |

| Working Height | 1,272mm |

| Tooling Opening Stroke | 140mm |

| Monitor | 10-inch touch panel with injection pressure monitoring system |

| Vacuum Molding | Optional |

| Internal Pressure Monitoring | Optional |

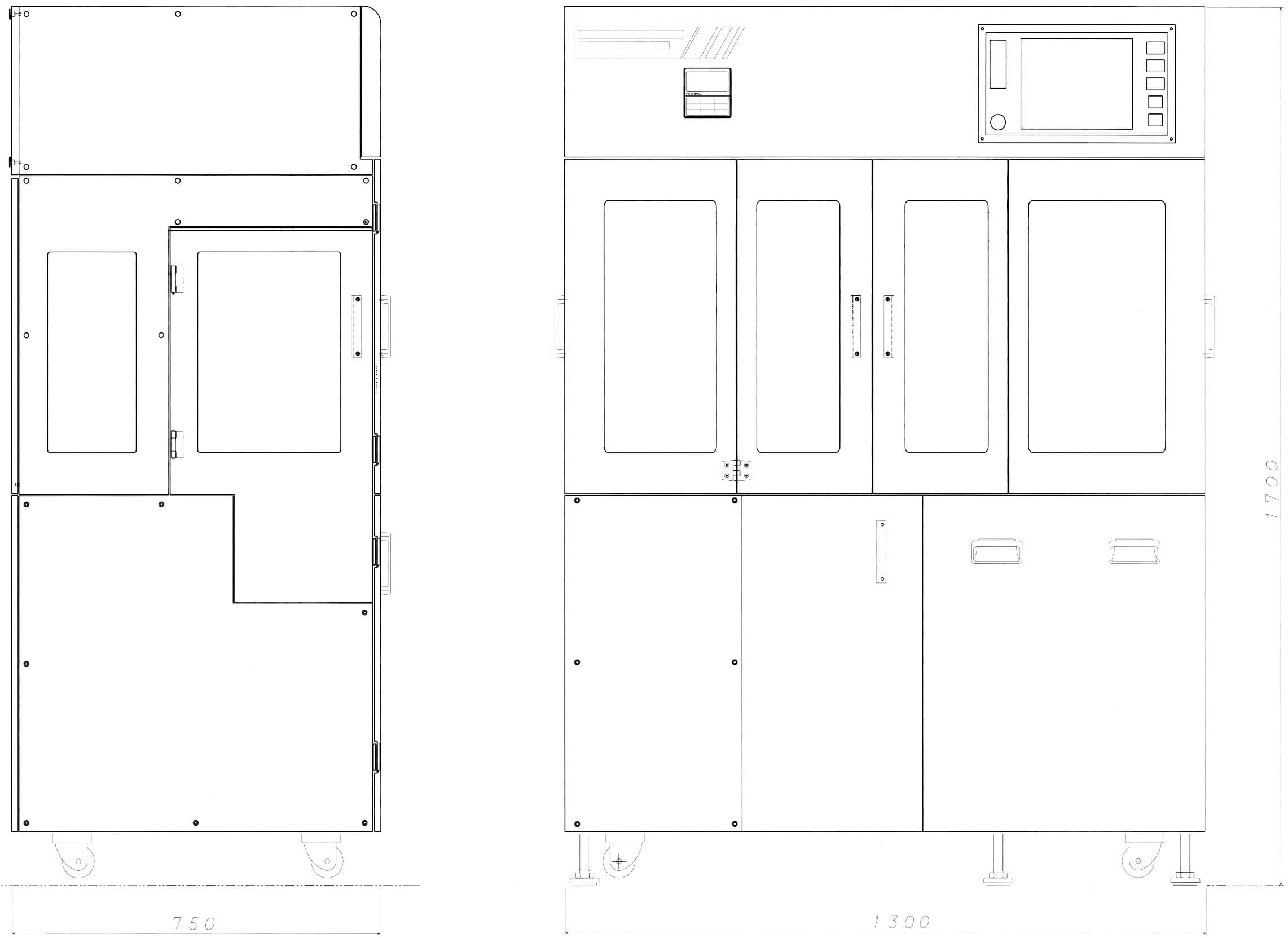

Across 2byX

This mass-production model is optimized for sealing semiconductor precision components. It supports 60 to 140 tons and features a high-efficiency design with machine cycle times as fast as 15 seconds.Both frame size and tooling count are customizable to meet specific needs, and the system offers excellent operability and maintainability.

Specification

| Equipment | Auto-mold device (convertor) | |||

|---|---|---|---|---|

| Press weight (tons) | 60ton | 100ton | 120ton | 140ton |

| Transfer pressure | 3.0ton | |||

| Work height | 1,270mm | 1,320mm | ||

| Mold Opening | 130mm | |||

| Machine time | Fastest time: under 15 seconds | |||

| Usable frame size | 280mm×80mm | 300mm×100mm | ||

・We offer other types of our Press Tooling Equipments. Kindly inform us for your further reference.

Lead Frame processing equipment

Fusion MTF1

This compact, space-saving trim/forming machine is designed for high-volume lead frame processing, including alignment and transfer to transport trays.Despite its small foot print, it delivers high productivity.Optional features include a 1.9-megapixel high-resolution camera for image inspection, displacement sensors, and dust/contamination prevention functions.

We offer customized designs tailored to your specific requirements.

Construction Example

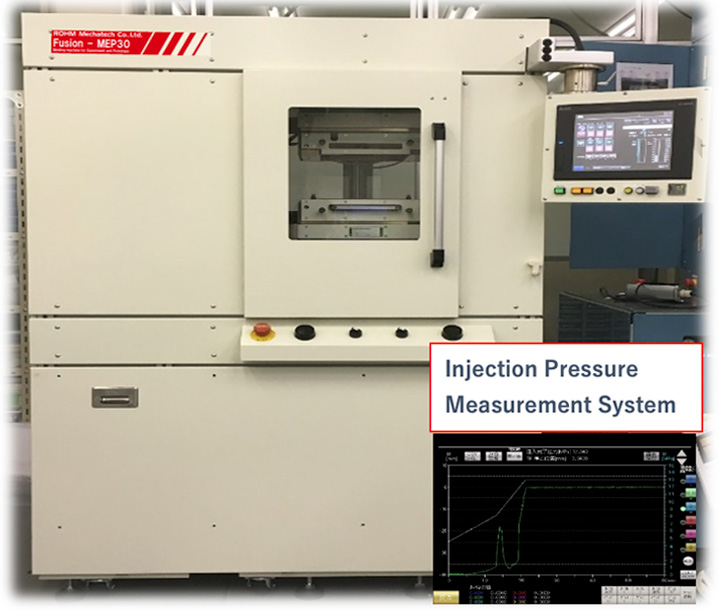

| Fusion MTF1 | Cutting, bending, individual piece separation, alignment and transfer to tray |

|---|---|

| Dimensions | H 1,700mm x W 1,400mm x D 700mm |

| Machine Weight | Approx. 1 ton (includes dust collector and tooling) |

| Press Capacity | 3 tons (dual-head servo press…60 SPM/unit) |

| Pressure Range | 0.5 to 3 tons (low-pressure control supported) |

| Compatible Frame Size | 70 × 240 mm (depends on tooling specifications) |

| Tooling Capacity | 1 to 2 toolings |

| Tray Size | 315 mm × 136 mm (JEDEC standard supported) |

| Working Height | 1,000 mm |

| Tooling Opening Stroke | 75 mm |

| Monitor | 9-inch touch panel (includes injection pressure monitoring) |

Fusion MTF2

This mass-production trim/forming machine is specialized for lead frame cutting and bending.It supports custom orders to flexibly meet diverse manufacturing needs.Optional features include a high-resolution 1.9-megapixel camera for image recognition, capable of detecting parts up to 780mm × 60mm within 50μs.Dust and contmaination prevention functions can also be added to suit your requirements.

Construction example

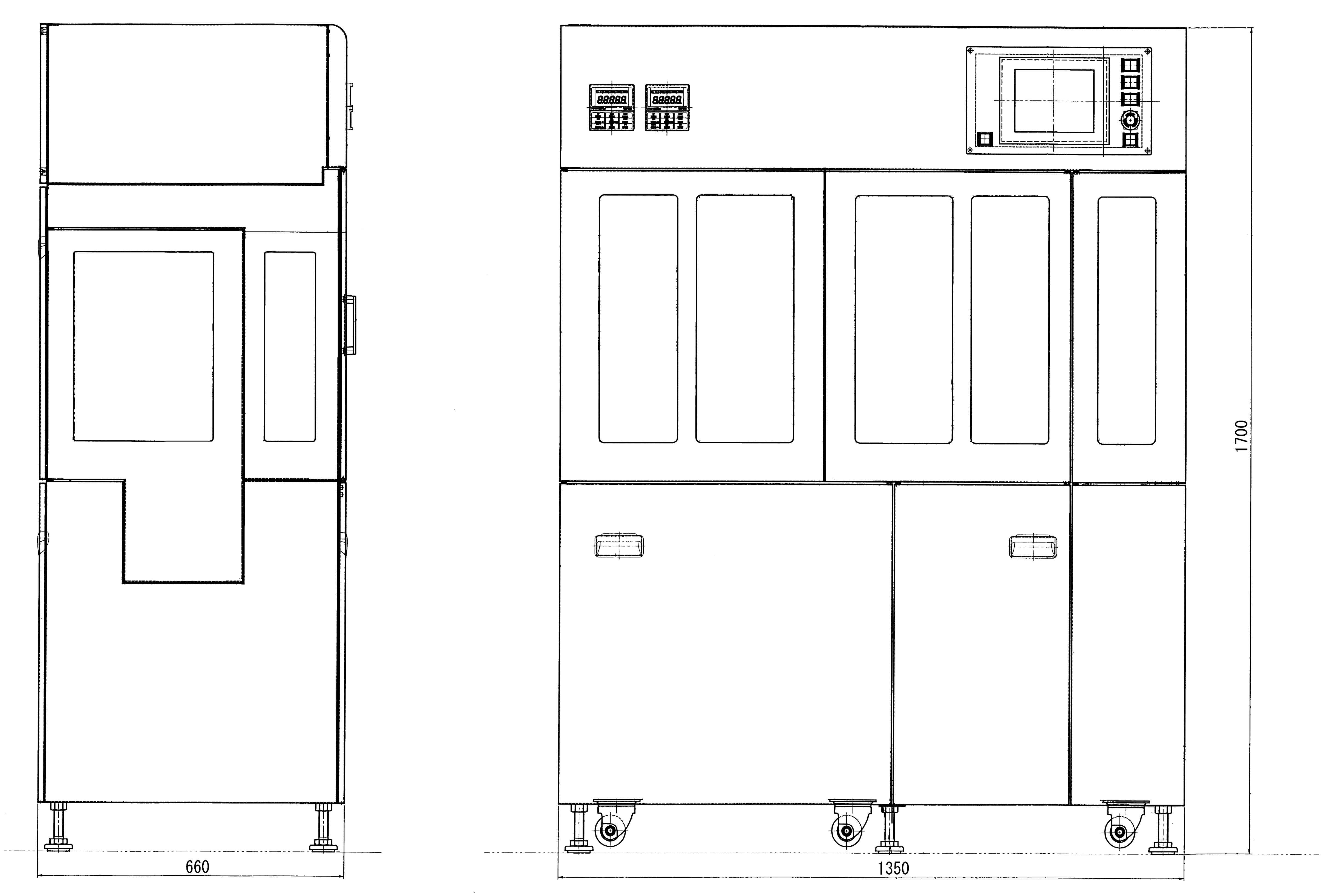

| Fusion MTF2 | Cutting, bending, individual piece separation, magazine-to-tube transfer |

|---|---|

| Dimensions | H 1,700mm × W 1,330mm × D 770mm |

| Power Supply | 3-phrase 200V |

| Press Capacity | 3 tons (single-head servo press; compatible with conventional tooling) |

| Weight | Approx. 0.7tons (includes tooling) |

| Compatible Frame Size | W 20~70mm × L up to 240mm |

| Processing Speed | Approx. 40~60pcs/min (Reference value) |

| QC STOP Function | Sampling inspection supported |

| Monitor | 9-inch touch panel |

Fusion MTF3

This mass-production trim/forming machine is specialized for lead frame cutting.

It supports magazine-to-magazine transfer and offers igh processing capacity in a compact, space-saving design. Optional features include a 1.9-megapixel camera for image inspection and dust/contamination prevention functions, supporting enhanced quality control.

Construction example

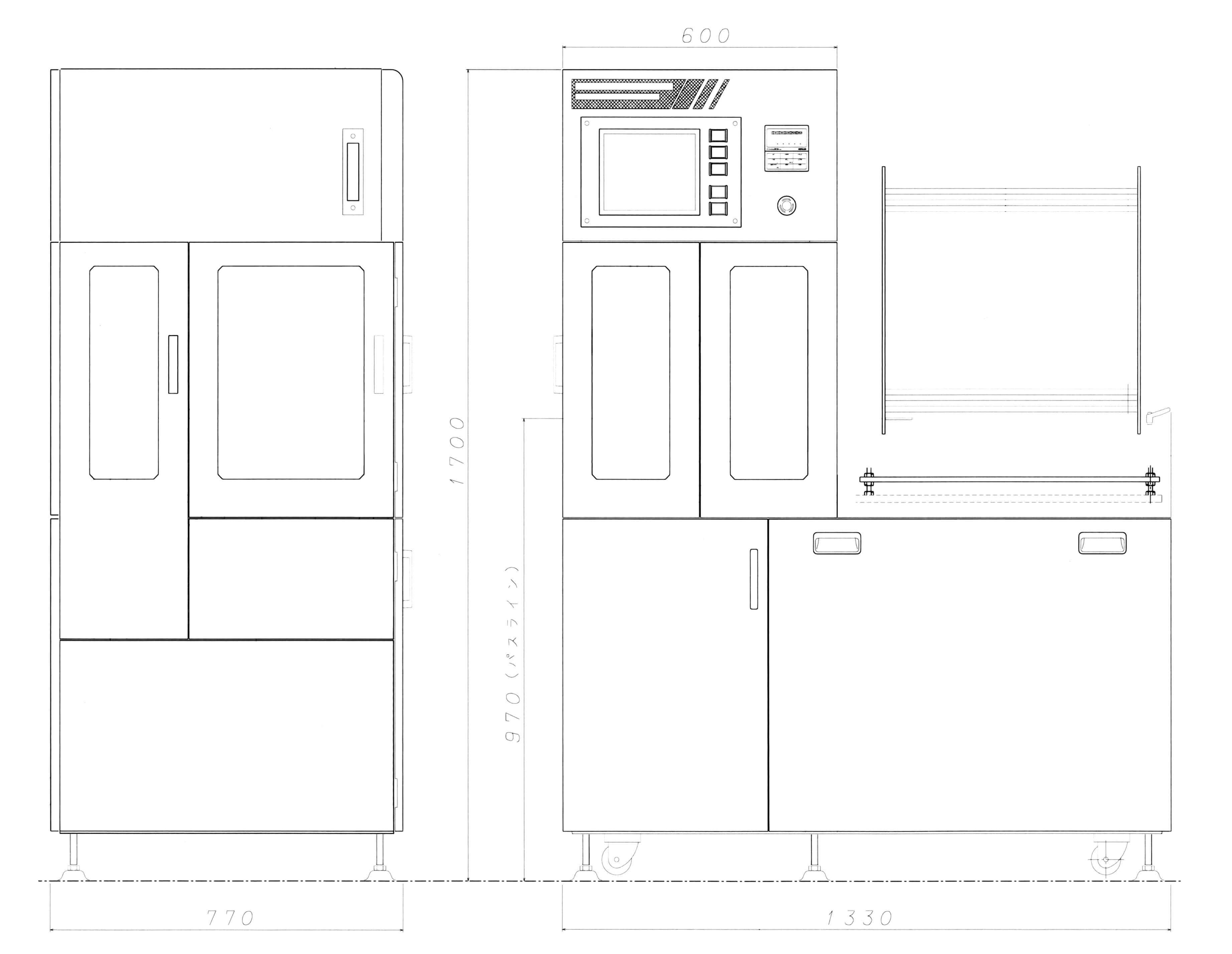

| Fusion MTF3 | Cutting process, magazine-to-magazine transfer |

|---|---|

| Dimensions | H 1,700mm × W 1,330mm × D 770mm |

| Weight | Approx. 0.7tons (includes tooling) |

| Power Supply | 3-phrase 200V |

| Press Capacity | 3tons (Single-head servo press) |

| Compatible Frame Size | W20~70mm × L up to 240mm |

| Processing Speed | Approx. 40~60pcs/min (Reference value) |

| Monitor | 9-inch touch panel |

Tabletop press equipment

RMS750(SERVO PRESS)

This tabletop servo press is specialized for lead frame trimming and supports both inline and standalone use.

Its compact design enables space-saving installation, while the AC servo motor and ball screw mechanism ensure energy efficiency and precise positioning.

Digital adjustment of open height allows compatibility with various tooling types, and customizable settings for transfer, position detection, and stop timing enables fine-tuned operation.

Construction example

| RMS750 | Cutting, Bending, and Piece Separation |

|---|---|

| Dimensions | H 580mm × W 390mm × D340mm (excluding protrusions) |

| Machine Weight | 50kg (excluding tooling) |

| Tooling Section | H 131mm × W 118mm × D 170mm |

| Drive System | Servo motor with ball screw & pulley |

| Pressing Capacity | Max 750kgf |

| Main Shaft Rigidity | 2.5kg |

| Ram Stroke | MAX 40mm |

| Max Speed | 15mm/sec |

| Workpiece Size | Max width 80mm (standard size) |

| Power Supply | AC100V |

| Overall Control | PLC |

Characteristics:

- Reduces power consumption by using an AC Servo-Motor

- Uses precision ball screws to allow high-accuracy positioning

- Digital configuration of the mold opening height allows the use of a variety of dies

- Highly configurable usage settings, including ram speed, height settings and stop timers

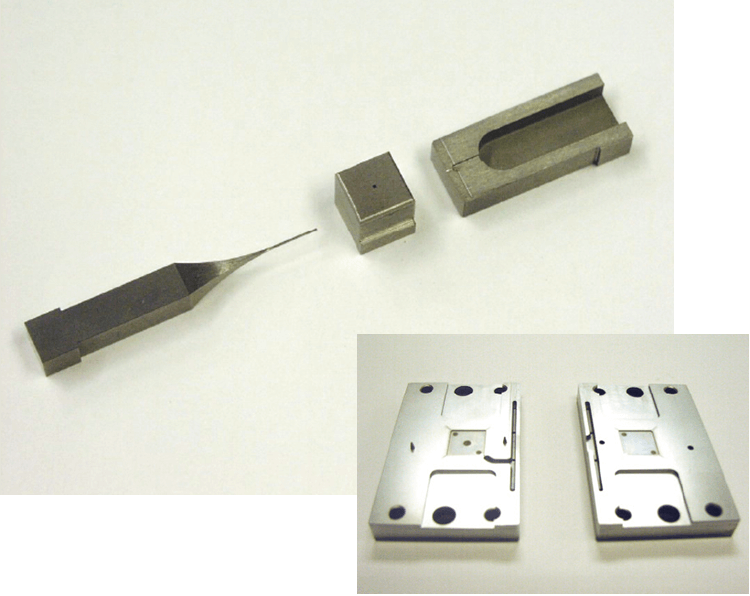

7 Days Experimental Service

Fastest Service in this industry, able to provide sample within 7 days only!

It takes 7days only to provide sample upon drawing of such as Leadframe, MOLD, FL(may vary depending on the specification)

More details