Leadframes Production

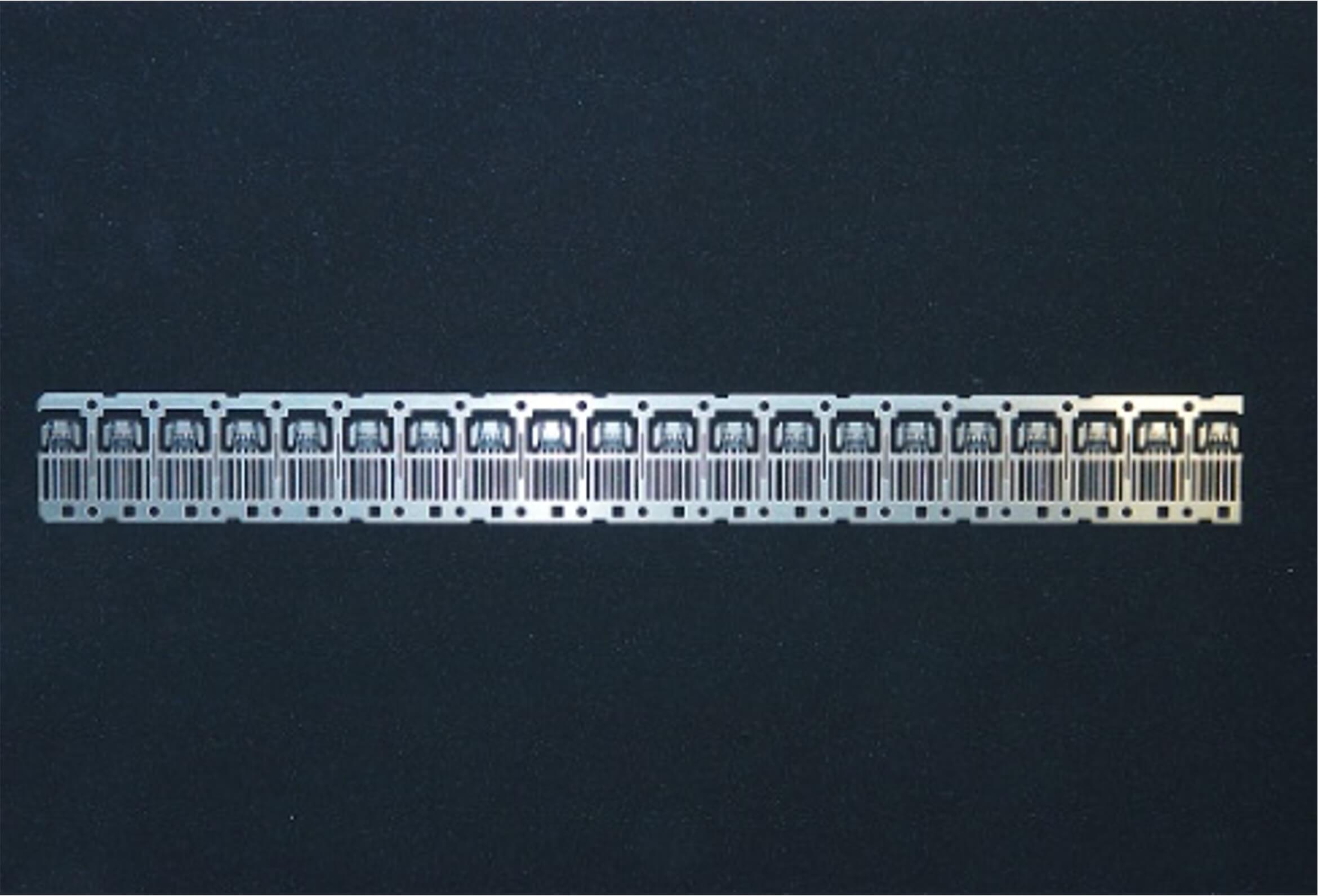

Mass-producing lead frames compliant with high-pin count and narrow pitch semiconductors

Our consistent mass-production technology supports high-quality Leadframes

Producing all types of lead frames

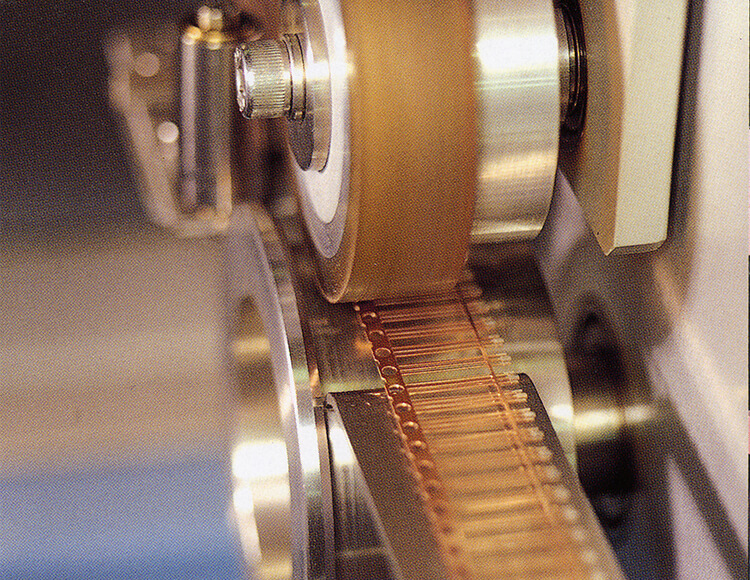

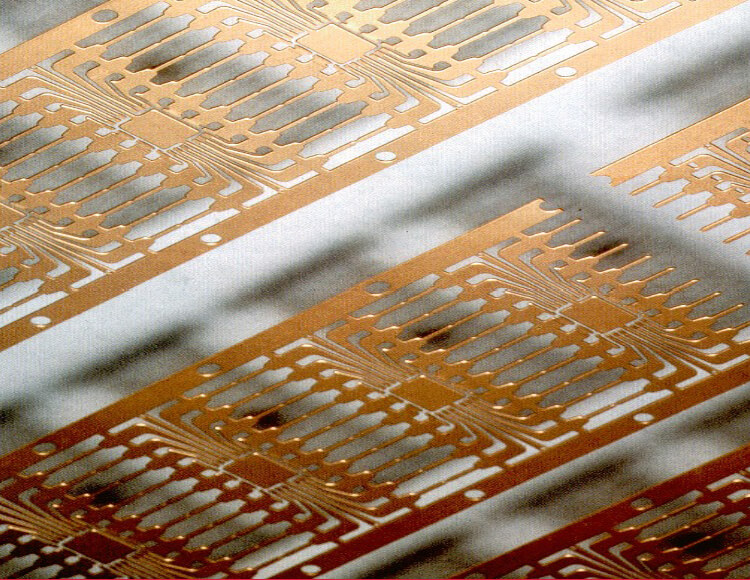

Semiconductors require an ever-expanding variety of lead frames to operate. ROHM MECHATECH supplies high-precision, top quality, mass-produced lead frames, with services ranging from die design and production to stamping die assembly.

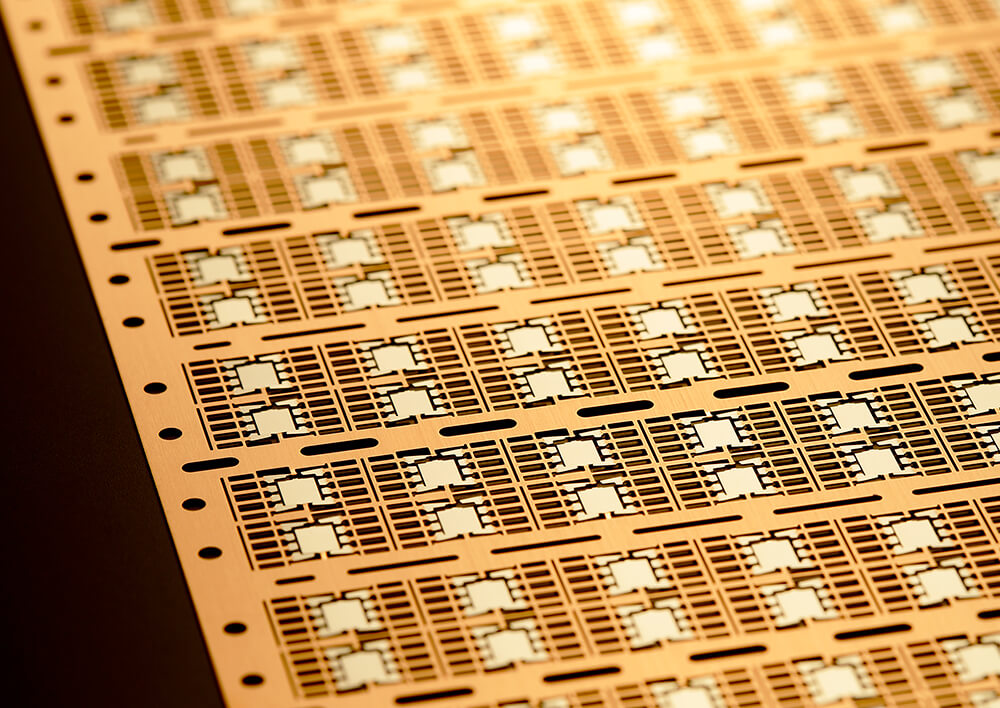

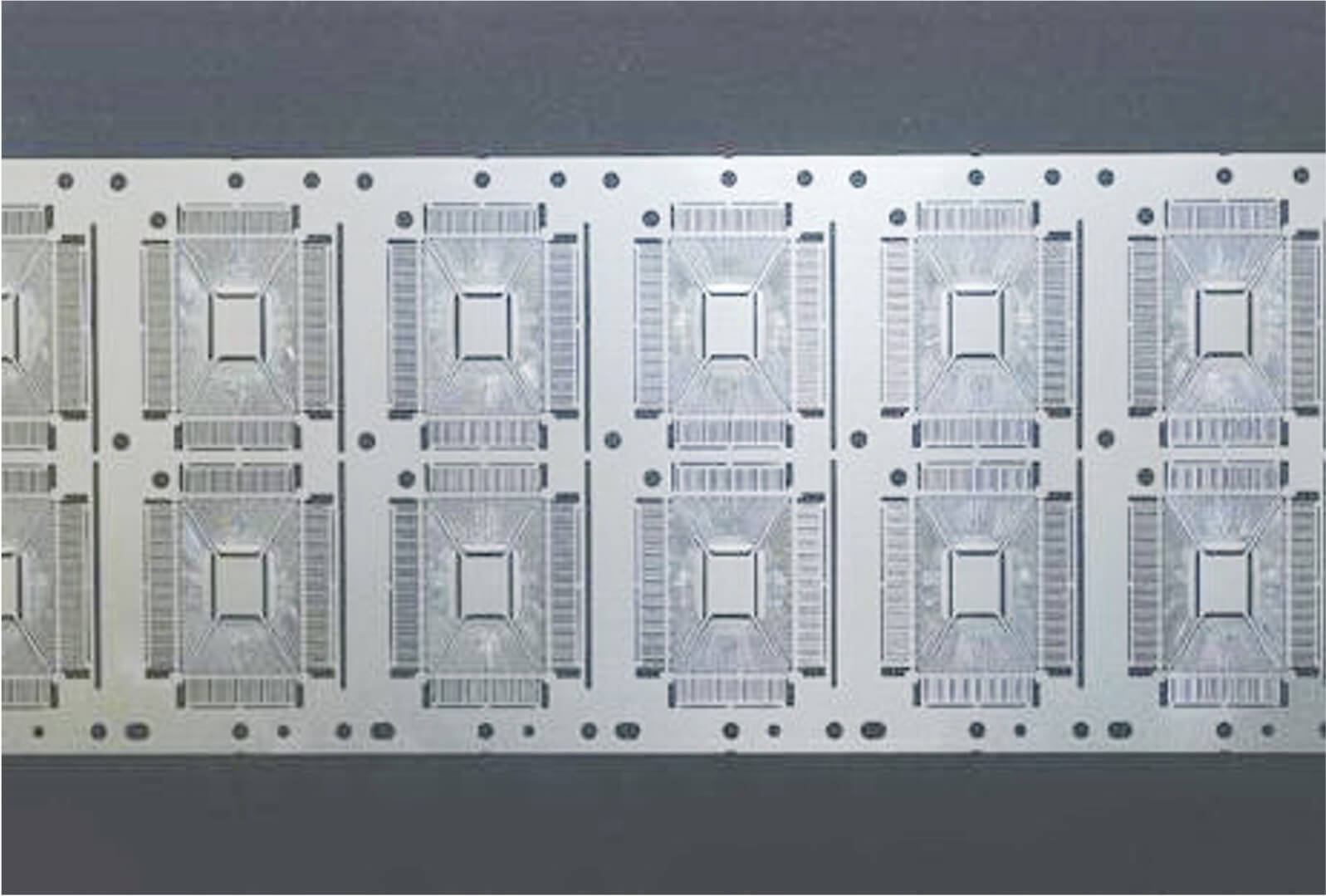

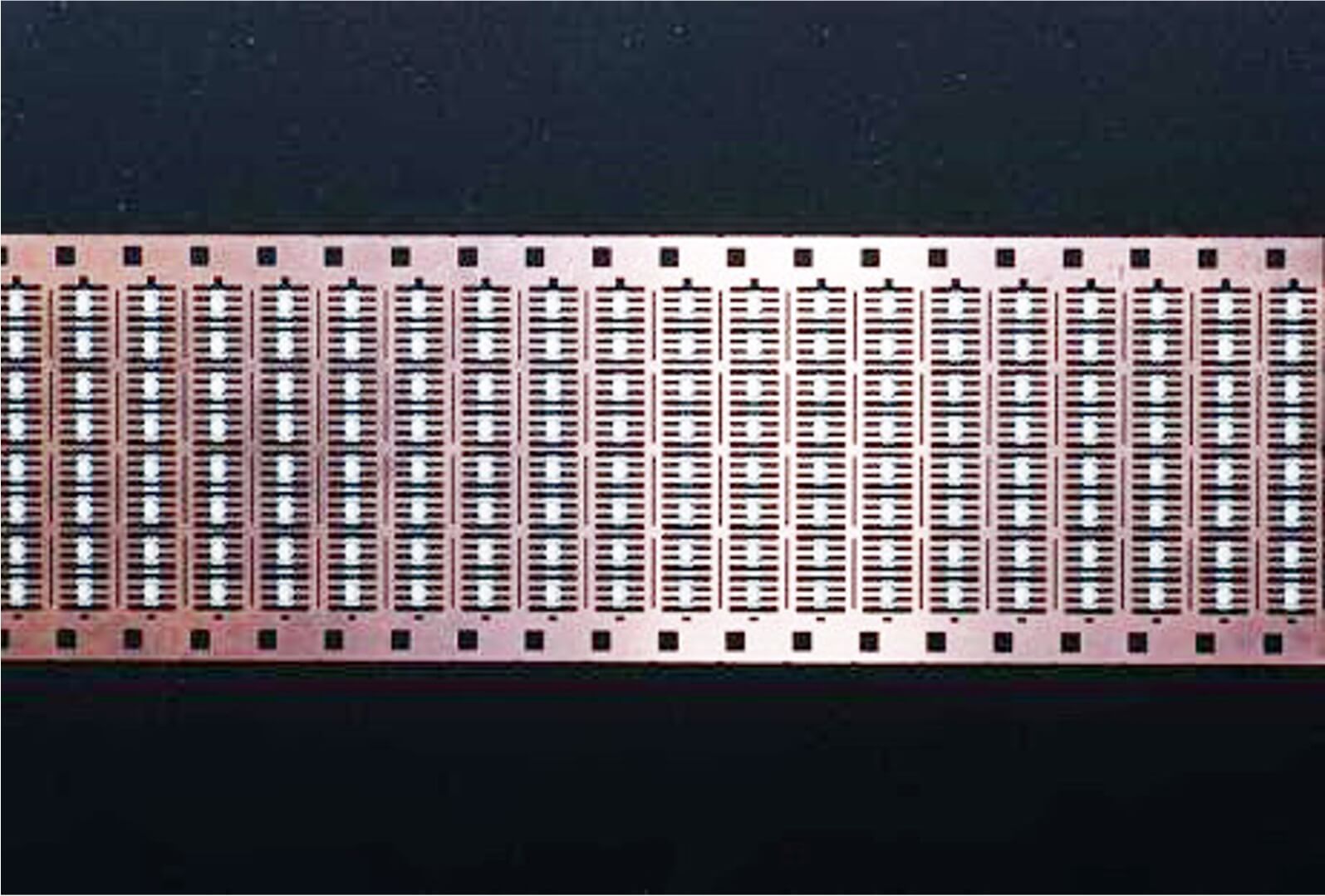

Punching width in minimum 80µm

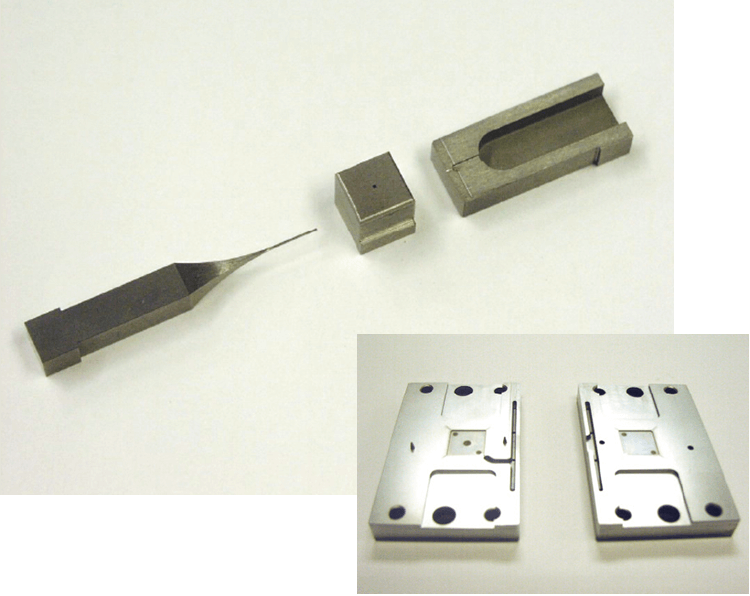

Stamping Die is skillfully assembled using high-precision components developed in-house. ROHM MECHATECH can meet our customer’s various requirements with advanced Die development and production capabilities and mass-production stamping technology.

Meeting all Leadframes needs

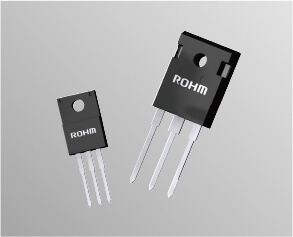

The Leadframes of semiconductor devices, such as ICs, transistors and diodes, are becoming increasingly diversified and are required to be higher in precision. ROHM MECHATECH has a cohesive mass production bases from design, fabrication, assembly, up to Leadframes production all in house.Together with overseas production bases, it enables to providestable product supply.

-

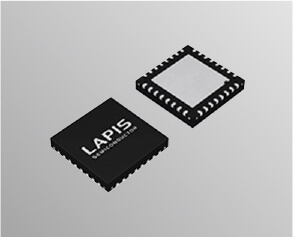

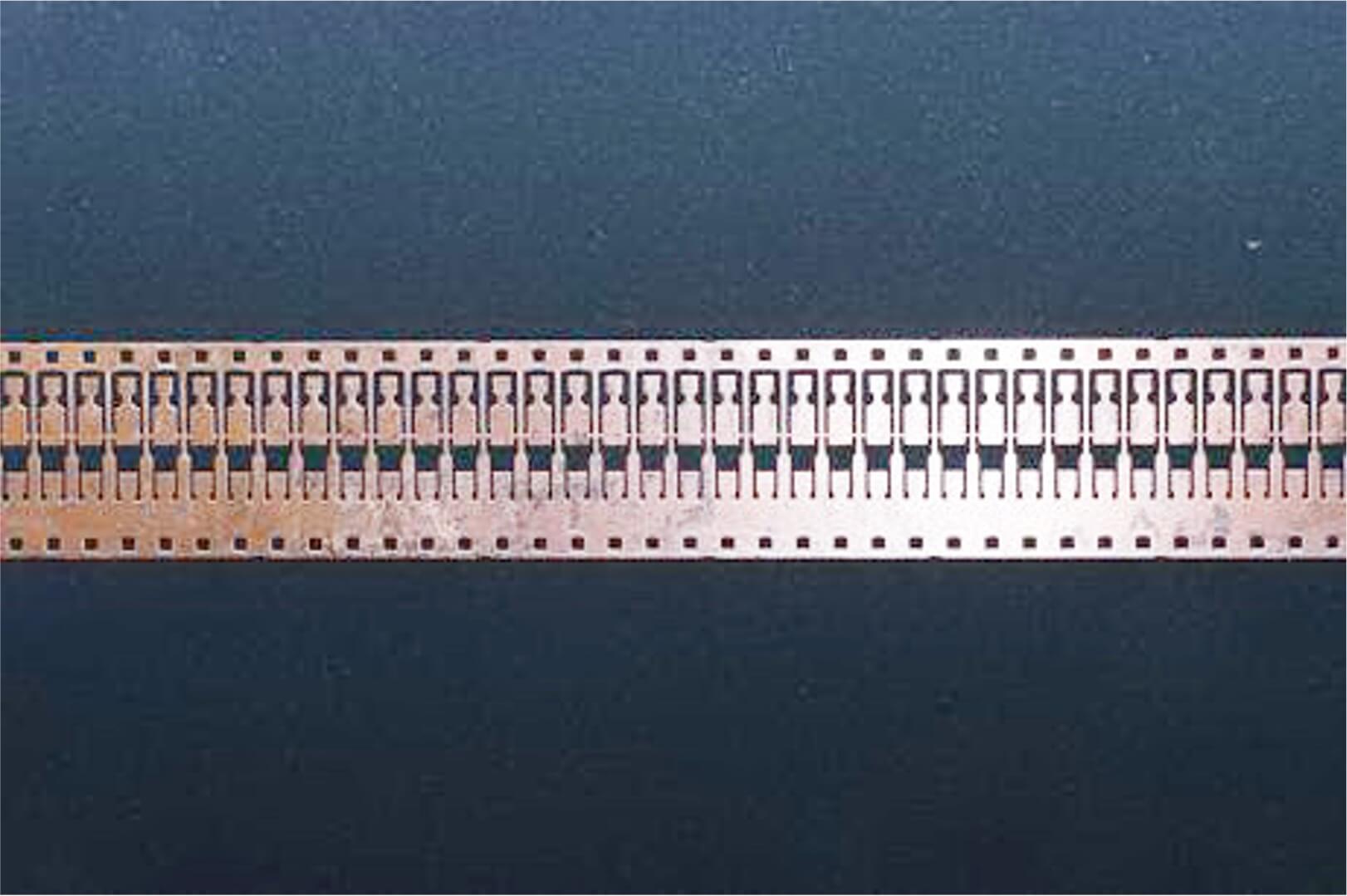

Monolithic ICs -

Laser Diodes -

Transistors -

Tantalum Capacitors

-

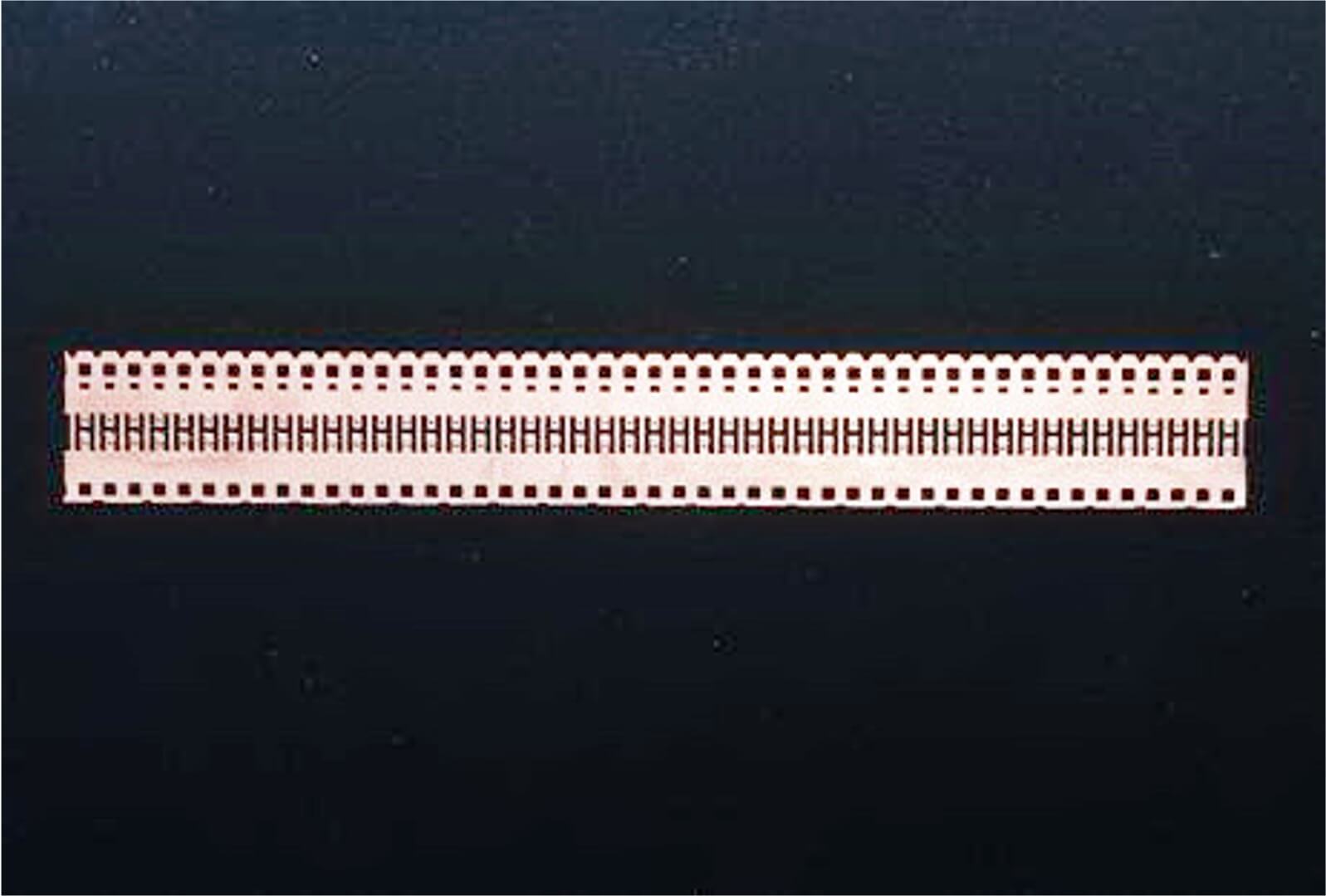

LSI -

Transistor -

Diode -

Tantalum Capacitors -

LED

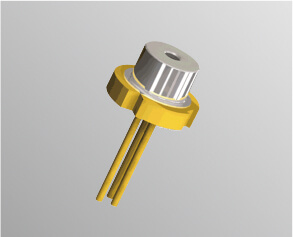

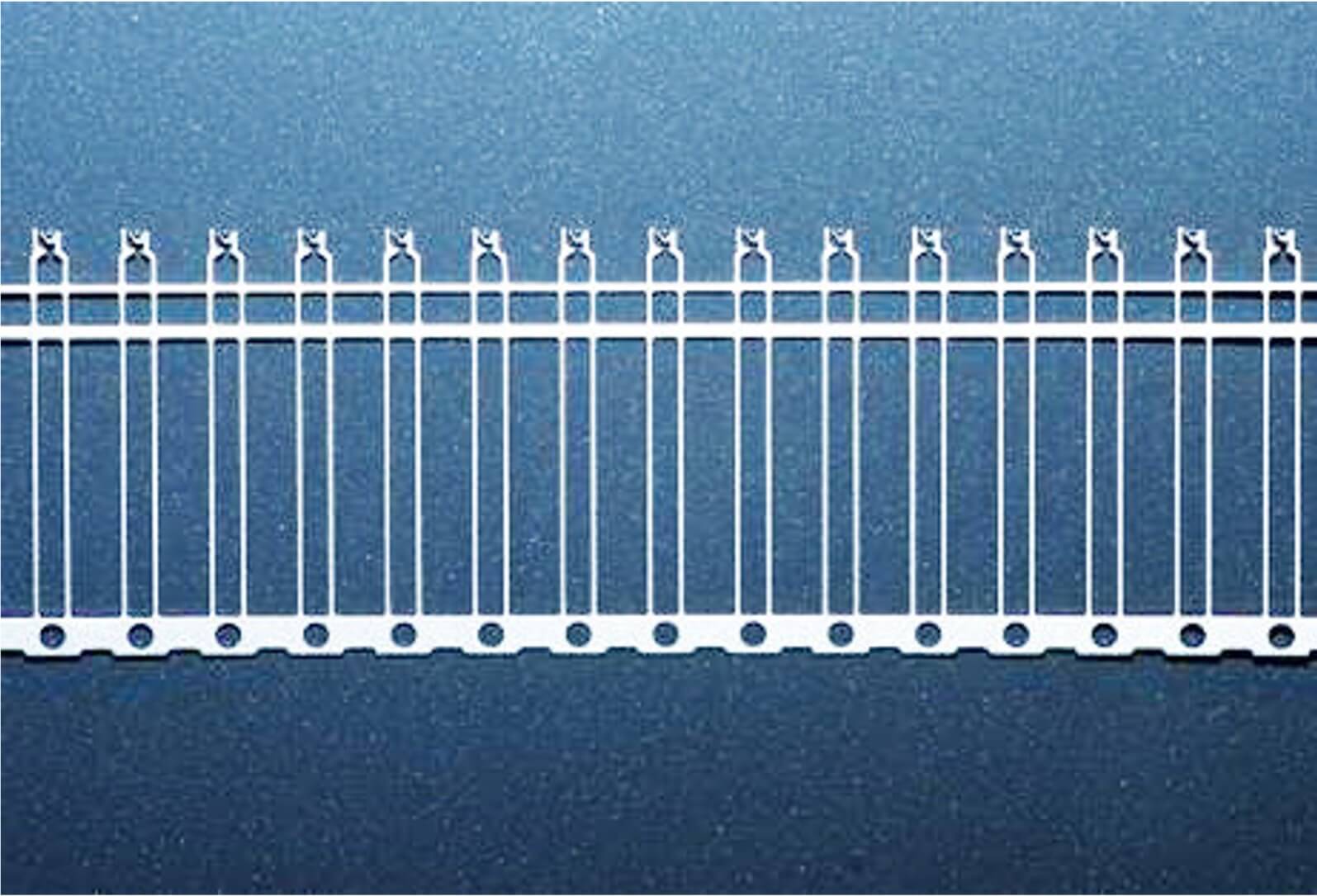

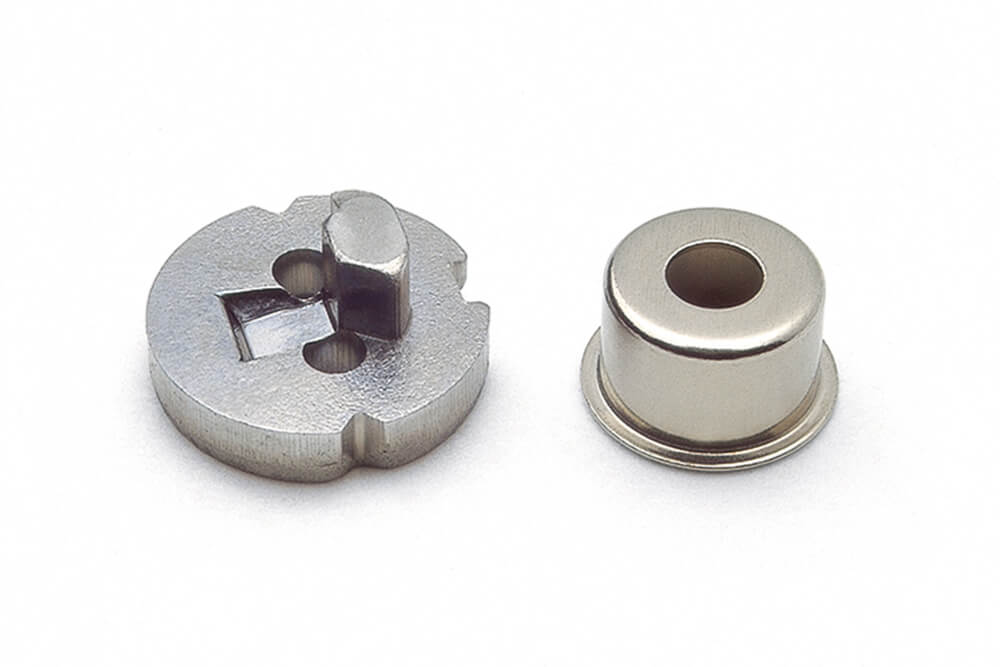

Laser Diode

-

Cap -

Stem

(/header,base) -

Slim

(Resin Stem)

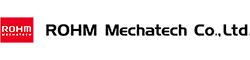

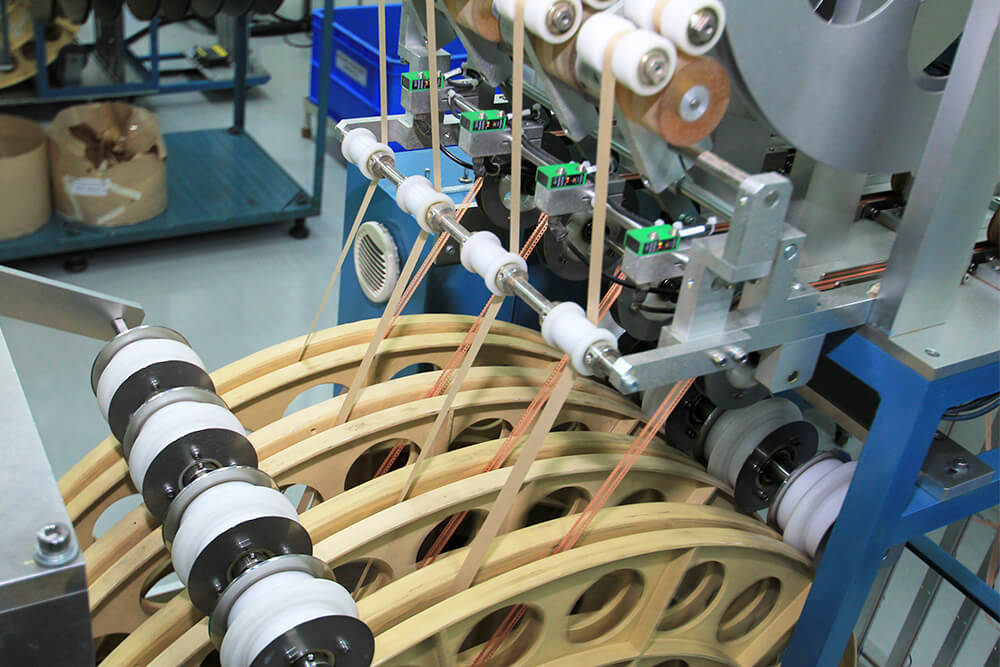

Stamping Process

Production bases in Japan and overseas have large-scale facilities that can mass-produce Leadframes. The sufficient capacity enables us to satisfy with customer needs promptly.

Plating Process

ROHM MECHATECH employs a variety of high-precision plating processes such as Spot-Ag, PPF plating, and Barrel Au plating meet customer needs.

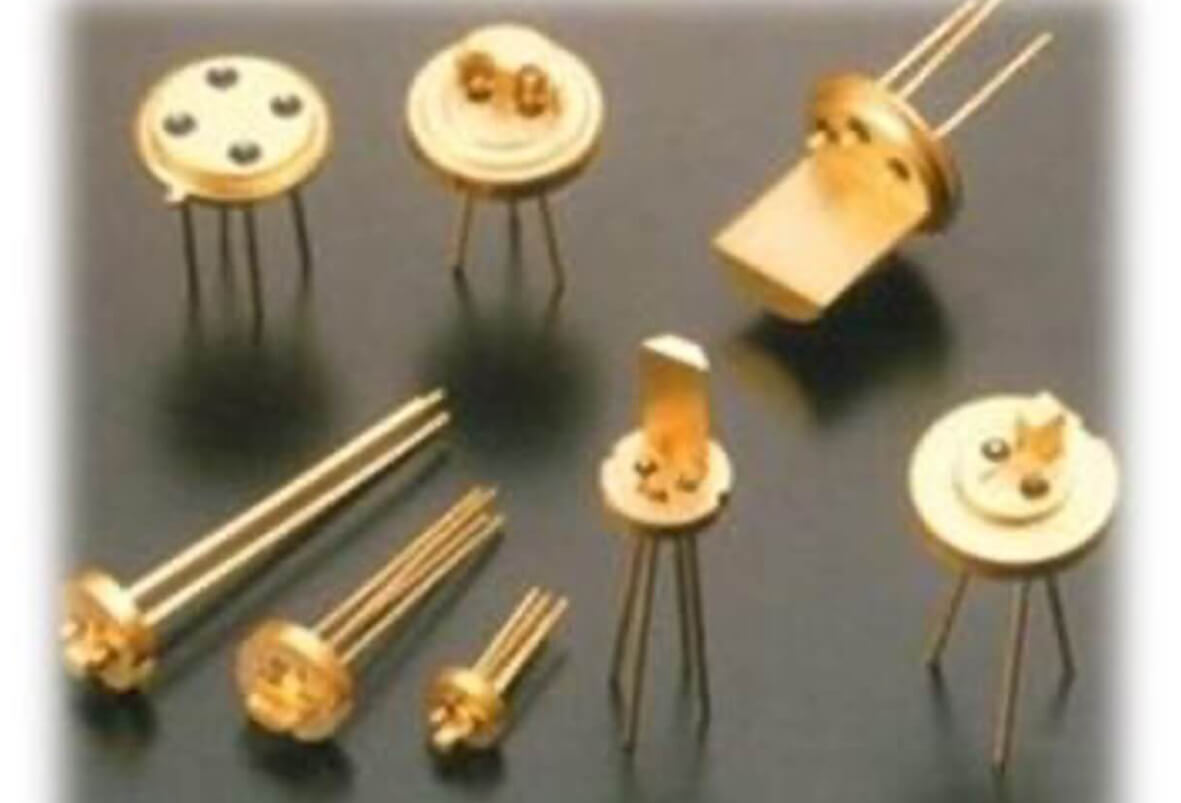

Technologies for mass production using forging and drawing

Stamping Dies are produced by hyperfine processes, such as forging, drawing, bending and extraction, all of which requires special know-how. The mass-production of stamping Dies is difficult. Under such circumstances, the mass-production technology developed by ROHM MECHATECH, which is based on the laser stem (/ header, base), is useful only when excellent die maintenance support is available. It is rated as one of the world’s highest technologies of this kind.

7 Days Experimental Service

Fastest Service in this industry, able to provide sample within 7 days only!

It takes 7days only to provide sample upon drawing of such as Leadframe, MOLD, FL(may vary depending on the specification)

More details